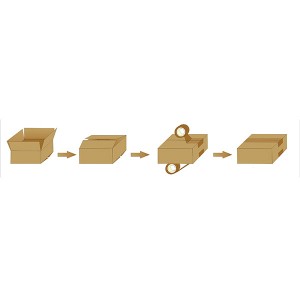

PriceList for Automatic Carton Case Erector and Automatic Carton Flap Folder Bottom Sealer

Our firm insists all along the quality policy of “product high quality is base of organization survival; consumer fulfillment could be the staring point and ending of an company; persistent improvement is eternal pursuit of staff” along with the consistent purpose of “reputation 1st, purchaser first” for PriceList for Automatic Carton Case Erector and Automatic Carton Flap Folder Bottom Sealer, We have ISO 9001 Certification and qualified this product or service .in excess of 16 years experiences in manufacturing and designing, so our goods featured with very best high-quality and aggressive rate. Welcome cooperation with us!

Our firm insists all along the quality policy of “product high quality is base of organization survival; consumer fulfillment could be the staring point and ending of an company; persistent improvement is eternal pursuit of staff” along with the consistent purpose of “reputation 1st, purchaser first” for China Erector and Case Erector Machine, The working experience in the field has helped us forged a strong relations with customers and partners both in domestic and international market. For years, our products and solutions have been exported to more than 15 countries in the world and have been widely used by customers.

Technical parameters:

Power supply: 380V 50HZ 5KW

Carton size: L200-500 W200-500 * H150-450mm

Packing speed :70-130 packs / min.

Packing: Single row / double row

Compressed air :0.5-0 .7 Mpa

Machine size: 2500 * 2000 * 1750mm

Product features:

● Taiwan technology manufacturing, and use of imported parts, electrical components and pneumatic components;

● Automatic folding carton cover, up and down automatically paste the tape, fast, smooth, beautiful;

● According to the specifications of the carton, manually adjust the width and height;

● equipped with blade protection device, to avoid accidental injury when the operation;

● easy to operate, can be stand-alone operation, but also with the use of automated packaging lines.