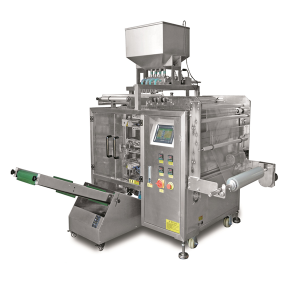

Hot sale Direct Automatic Weighing Filling Packing Machine Nuts Packaging Machine For Sale

With reliable excellent approach, great name and ideal consumer services, the series of products and solutions produced by our company are exported to many countries and regions for Hot sale Direct Automatic Weighing Filling Packing Machine Nuts Packaging Machine For Sale, Generate Values,Serving Customer!” is the intention we pursue. We sincerely hope that all clients will establish long term and mutually effective cooperation with us.In case you wish to get additional particulars about our business, Remember to speak to with us now.

With reliable excellent approach, great name and ideal consumer services, the series of products and solutions produced by our company are exported to many countries and regions for Automatic Nuts Packaging Machine, Directpacking Machine, Weighing Filling Packing Machine, The development of our company not only needs the guarantee of quality, reasonable price and perfect service, but also relies on our customer’s trust and support! In the future, we’ll continue with the most experienced and high quality service to supply the most competitive price, Together with our customers and achieve win-win! Welcome to inquiry and consult!

Applicable for weighing of granular, bar-shaped products, such as sunflower / melon seeds, almonds, pistachios, pine nuts, candies, puffed food, beans, frozen food, pet food, snacks, hardware and chemicals.

|

Max. Cap.(g) |

800-1500g |

|

Weighing Accuracy(g) |

0.5-2g |

|

Weighing head number |

10/14/20/32 |

|

Max. Weighing Speed |

70WPM |

|

Hopper Volume |

1600/2500ml |

|

Control Panel |

7.0″/10″ LCD Touch Screen |

|

Options |

Dimple Plate/Timing Hopper/Printer/Rotary Top Cone |

|

Driving System |

Step Motor |

|

Power Requirements |

220V / 1000W / 50/60HZ / 10A |

|

Packing Dimension(mm) |

1720 (L)x1100 (W)x1100 (H) |

|

Gross WGT |

420KG |

1. Professional digital weighing module with high precision and good stability

2. Control system: MCU or PLC (optional).

3. Touch screen interface has different levels of authorized access; up to 16 different languages for choice; application software upgraded through USB.

4. Factory parameters recovery function; 99 preset product parameters to meet different parameter program requirements.

5. Weighing hopper able to discharge in turn to effectively prevent products from blocking.

6. Weighing and counting function to meet diverse needs from customers.

7. Real-time display of amplitude of each vibration pan as well as product weight in each hopper to better monitor the running status of the machine.

8. Machine body with SUS304/316 for option; IP65 dust and waterproof design.

9. Cleaning function: able to make the hoppers in opening state for easy daily cleaning and maintenance.

10. Modular design of control system for easy maintenance and cost-saving.