factory Outlets for Blister Packaging Machine Pharmaceutical Jam Chocolate Olive Oil Calcium Tablet Blister Packing Machine

“Control the standard by the details, show the power by quality”. Our organization has strived to establish a highly efficient and stable employees team and explored an effective high-quality command method for factory Outlets for Blister Packaging Machine Pharmaceutical Jam Chocolate Olive Oil Calcium Tablet Blister Packing Machine, Many years of work experience, we have realized the importance of giving top quality solutions and also the ideal before-sales and after-sales solutions.

“Control the standard by the details, show the power by quality”. Our organization has strived to establish a highly efficient and stable employees team and explored an effective high-quality command method for Electric Blister Packing Machine, Liquid Blister Packing Machine, Olive Oil Blister Packing Machine, We follow superior mechanism to process these products and solutions that ensure optimum durability and reliability of the merchandise. We follow latest effective washing and straightening processes that allow for us to provide unmatched quality of solutions for our clients. We continually strive for perfection and all our efforts are directed towards attaining complete client satisfaction.

Product Description

Product Category

Company Information

Certifications

FAQ

Contact Us

Product Description

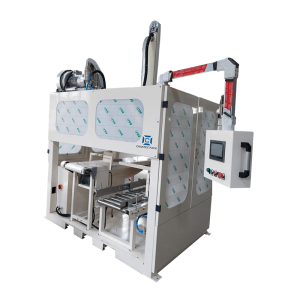

Accept max carton width 190mm, click to check working video

Main technical parameters:

|

Item/Model |

CX-190W-A |

|

Packaging rate |

30~80 cartons/min |

|

Carton size range |

L(100-300)mm×W(40-190)mm×H(30-80)mm |

|

Carton paper requirement |

300-400g/m3 |

|

Motor power |

2.1 kW |

|

Power supply type |

3-phase 4-line system, 380V 50Hz |

|

Machine noise |

≤80dB |

|

Air supply source |

0.5-0.8 MPa |

|

Air consumption |

150-200 L/min |

|

External dimensions |

3700×2200×1800 mm |

|

Overall weight |

1600 kg |

Main performance and structural characteristics:

1、Adopts the packaging form of automatic material feeding, carton opening, carton entrance, lot number printing, carton sealing and waste rejection, etc., its structure is compact and reasonable and its operation and adjustment are simple; Adopts servo/stepping motor, touch screen and PLC system, and the man-machine interface displays clearer and more convenient operation, has high degree of automation and is more humanized;

2、Adopts photoelectric eye automatic detection and tracking system, empty packs are not fed into the carton, thus maximally saving packaging material; Large range of packaging makes adjustment convenient, and quick switching can be achieved between different specifications and dimensions;

3、Specification change does not require mould change, and is achieved just through adjustment;

4、Adopts automatic shutdown when items are not fed in the designated position in the carton and overload protection device of main drive motor, which is safer and more reliable in application;

5、Adopts upturning safety shield according to the requirements of the customer, which is easy to operate and has nice appearance.

6、Can realize linked production with such equipments as aluminum-plastic packaging machine, pillow type packaging machine, 3D packaging machine, bottled line, filling machine, labeling machine, coding machine, online weighing instrument and other production lines;

7、Various types of automatic material feeders and carton entrance systems according to requirements of the material to be packaged;

8、Hot melt adhesive coating machine can be optionally equipped according to customer requirements and adopt hot melt adhesive to seal the carton through glue spray and seal the carton through mechanical brushing.

Product Category

Automatic Top Load gravity case packer

Automatic Robotic Pick and Place Case Packer

Automatic Side load case packer Robotic Loaders & Tray Loading

Company Information

1. Hefei IECO Intelligent Equipment CO.,LTD(CHANTEC PACK)is located in Hefei City, Anhui Province – one of the most famous science and education cities in China.

2. IECO is the professional manufacturer of vertical packaging machine(pillow bag, gusset bag, quad bag), multi-lane packaging machine(4side sealing bag, back sealing bag), premade bag rotary packaging machine(doypack, zipper pouch), case packing line(bottle into case, bag into case) and bag into bag secondary packing line.

3. IECO continuously focuses on R & D, production, installation and service of packaging machinery. It has a well experienced engineers team focused on packing industry for over 10years to design the customerised packing machine according to your own packing requirement, like product characteristics, workshop layout and sales market.

4. IECO always follow the standard of “reduce packaging costs, but keep the quality”.

5. IECO have accieved ISO9001 and CE certification

6. IECO could offer door-to-door service anywhere in the world. Remote guidance also could be offer by cell and network before and after sales.

Certifications

1. 20years experience for fully auto packing machine

2. We have approved by CE

3. 24hours services and 12months guarantee

4. Can offer the technician to overseas for commissioning

FAQ

1. Q: What is your best price for this product?

A: The price is negotiable. It can change according to your quantity or package.When you are making an inquiry, please let us know the quantity you want.

2.Q: You are a factory or trading company?

A: We are a factory located in Anhui province, Hefei city. And we have customer in Africa, Europe, South America, Asia and North America. Please share your packing requirements, then we will try to recommand you most suitable model and our former cutomer’s factory working video.

3.Q: Why choose us?

A: Professional and experienced R&D team,reliable and strict quality control system. We test all our products before shipment to make sure everything in perfect condition.

4.Q: What is the MOQ?

A: We accept the small amount products, our MOQ is 1 Set

5.Q: How does this product packed usually?

A: One Set in sea-transportation standard box.

Contact Us