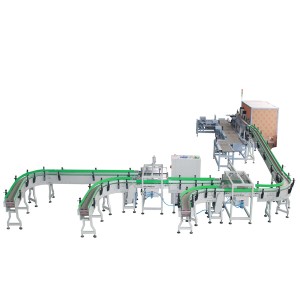

Automatic vertical washing powder, cereal, salt carton box cartoning packing machine

Video description:

Main technical parameters:

|

No. |

Equipment name |

Technical parameters |

|

1. |

Main motor power |

1.5Kw |

|

2. |

Conveyor motor power |

0.37Kw |

|

3. |

Packing speed | about 60-70 boxes/min for customer’s size |

|

4. |

Canton size(L×WxH) |

Min. 80x30x140 mm. Max. 200x100x280 mm. |

|

5. |

Total power | ≈15Kw |

|

6. |

accuracy | 5‰ |

|

7. |

size | 5500×3000×2100mm(L×W×H) |

|

8. |

noise |

<85DB |

|

9. |

weight |

1200KG |

Main performances and structure features:

1. Packing forms such as automatic feeding,weighing and caculate,opening box,feeding,spraying glue and sealing box, waste rejecting, etc. are adopted. Featured by compact and reasonable structure, simple operation and adjustment.

2. Servo/step motor, touch screen, PLC control system and man-machine interface display make operation more clear and convenient. With high automation degree, the machine is more user-friendly.

3. The photoelectric eye automatic detection tracking system is adopted. No boxing is made if the bag is empty, so as to save packing materials to the utmost extent.

4. With wide packing range and convenient adjustment, fast switching among various specifications and sizes can be realized.

5. Change of specifications does not need change of molds, but can be realized through adjustment.

6. Automatic stopping is available when the material boxing is not in place, and the main driving motor overload protection device is used, so that the machine is safer and more reliable.

7. According to customer requirements, the upturning type safety protective cover is adopted, which is featured by simple operation and beautiful appearance.

8. Linked production with the labeling machine, ink jet printer, online weightometer, three-dimensional packing machine and other production lines and equipment can be realized.

9. Various automatic feeders and boxing systems can be designed according to different requirements of packing materials.

10. According to customer requirements, the hot melt glue machine can be equipped, and the hot melt glue spreading and box sealing and mechanical glue brushing and box sealing can be adopted.

1. Hefei IECO Intelligent Equipment CO.,LTD(CHANTEC PACK)is located in Hefei City, Anhui Province – one of the most famous science and education cities in China.

2. IECO is the professional manufacturer of vertical packaging machine(pillow bag, gusset bag, quad bag), multi-lane packaging machine(4side sealing bag, back sealing bag), premade bag rotary packaging machine(doypack, zipper pouch), case packing line(bottle into case, bag into case) and bag into bag secondary packing line.

3. IECO continuously focuses on R & D, production, installation and service of packaging machinery. It has a well experienced engineers team focused on packing industry for over 10years to design the customerised packing machine according to your own packing requirement, like product characteristics, workshop layout and sales market.

4. IECO always follow the standard of “reduce packaging costs, but keep the quality”.

5. IECO have accieved ISO9001 and CE certification

6. IECO could offer door-to-door service anywhere in the world. Remote guidance also could be offer by cell and network before and after sales.

1..Q: You are a factory or trading company?

A: We are a factory located in Anhui province, Hefei city. And we have customer in Africa, Europe, South America, Asia and North America. Please share your packing requirements, then we will try to recommand you most suitable model and our former customer's factory working video.

2..Q:What is your guarantee of machine ?

A: 1 year since machine arrive at customer's factory.

3.Q: Why choose us?

A: Professional and experienced R&D team,reliable and strict quality control system. We test all our products before shipment to make sure everything in perfect condition.

4.Q: Can you arrange your technicians to install the machine for us?

A: Yes,we will assign our engineers to go abroad for installing machines for our clients. And if you have engineer team, we also provide instruction manual in English, spare parts and tools for installation.